5 Cheaper Alternatives to Inexpensive Prefab Houses

Discover 5 cheaper alternatives to an inexpensive prefab house. Compare costs, options, and tips to build your budget-friendly home!

The Real Cost of Affordable Housing: Exploring Inexpensive Prefab Houses

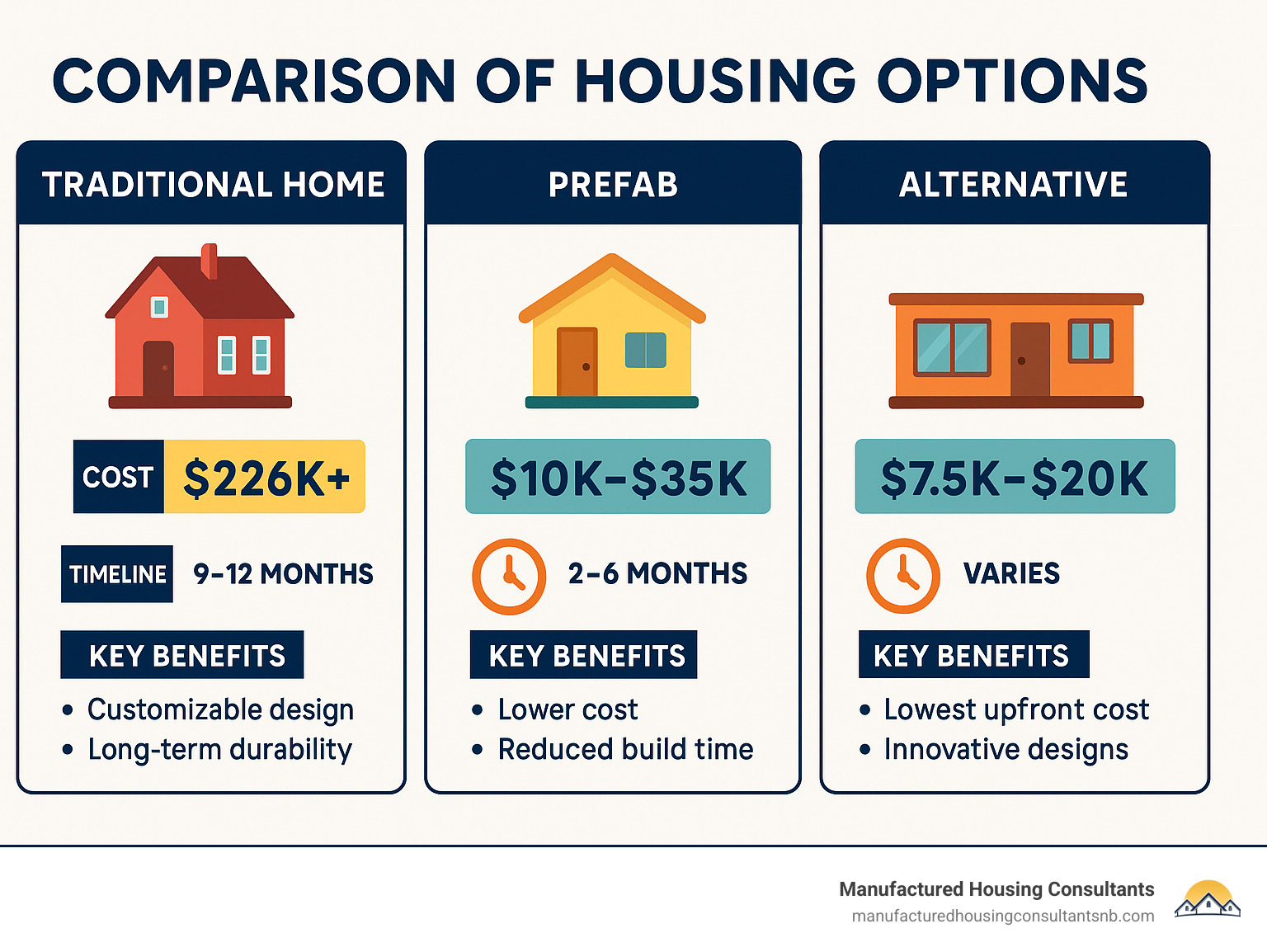

Inexpensive prefab houses typically cost between $10,000 and $35,000, significantly less than traditional site-built homes. Most affordable options include:

- Basic tiny prefabs: $7,500-$20,000

- Container-based homes: $10,000-$35,000

- Small modular units: $16,599-$40,000

- Expandable models: $20,000-$50,000

- Steel frame kits: $30,000-$60,000

In today’s housing market, where the average new home construction costs between $121,099 and $502,765, finding an affordable path to homeownership feels nearly impossible. Rising material costs, labor shortages, and lengthy construction timelines have pushed traditional housing out of reach for many Americans like you.

That’s where prefab housing enters the picture.

Prefab homes (short for prefabricated) are built in sections at a factory, then transported and assembled on-site. This manufacturing approach dramatically reduces both costs and construction time. The controlled factory environment eliminates weather delays, reduces material waste to under 5% (compared to 25% in traditional construction), and allows for precise quality control.

“The tiny house movement continues to gain momentum as an efficient, eco-friendly living solution,” notes a recent industry report. This momentum isn’t just about going small—it’s about smart construction that maximizes value while minimizing environmental impact.

Whether you’re looking for a primary residence, vacation property, or income-generating rental, understanding your options beyond traditional construction can open doors to homeownership you might have thought were closed.

But are inexpensive prefab houses truly the most affordable path to homeownership? Or might there be even more budget-friendly alternatives worth exploring?

Inexpensive prefab house terms to learn:

Cheaper Paths Than Buying an Inexpensive Prefab House

While inexpensive prefab houses have certainly changed the affordable housing game, we’ve finded several alternatives that might stretch your dollar even further. At Manufactured Housing Consultants, we’re all about finding you the perfect home—even if that means thinking outside the traditional prefab box. These options often come with smaller price tags, less complexity, and sometimes, you can move in faster too!

Here’s something we’ve learned from helping hundreds of Texas families find homes: that advertised base price? It’s just the beginning of the story. When you’re considering an inexpensive prefab house, additional costs can sneak up on you. Delivery fees might run you $2,000-$5,000 depending on distance. You’ll need a foundation ($5,000-$15,000), utility hookups ($3,000-$10,000), permits ($500-$2,000), and site preparation ($1,000-$5,000). And don’t forget those finishing touches not included in the sticker price!

These “not-so-hidden” extras can boost your total investment by 30-50% above what you initially budgeted. Some of the alternatives we’re about to explore either include more of these costs upfront or eliminate them entirely—which means fewer surprises for your wallet.

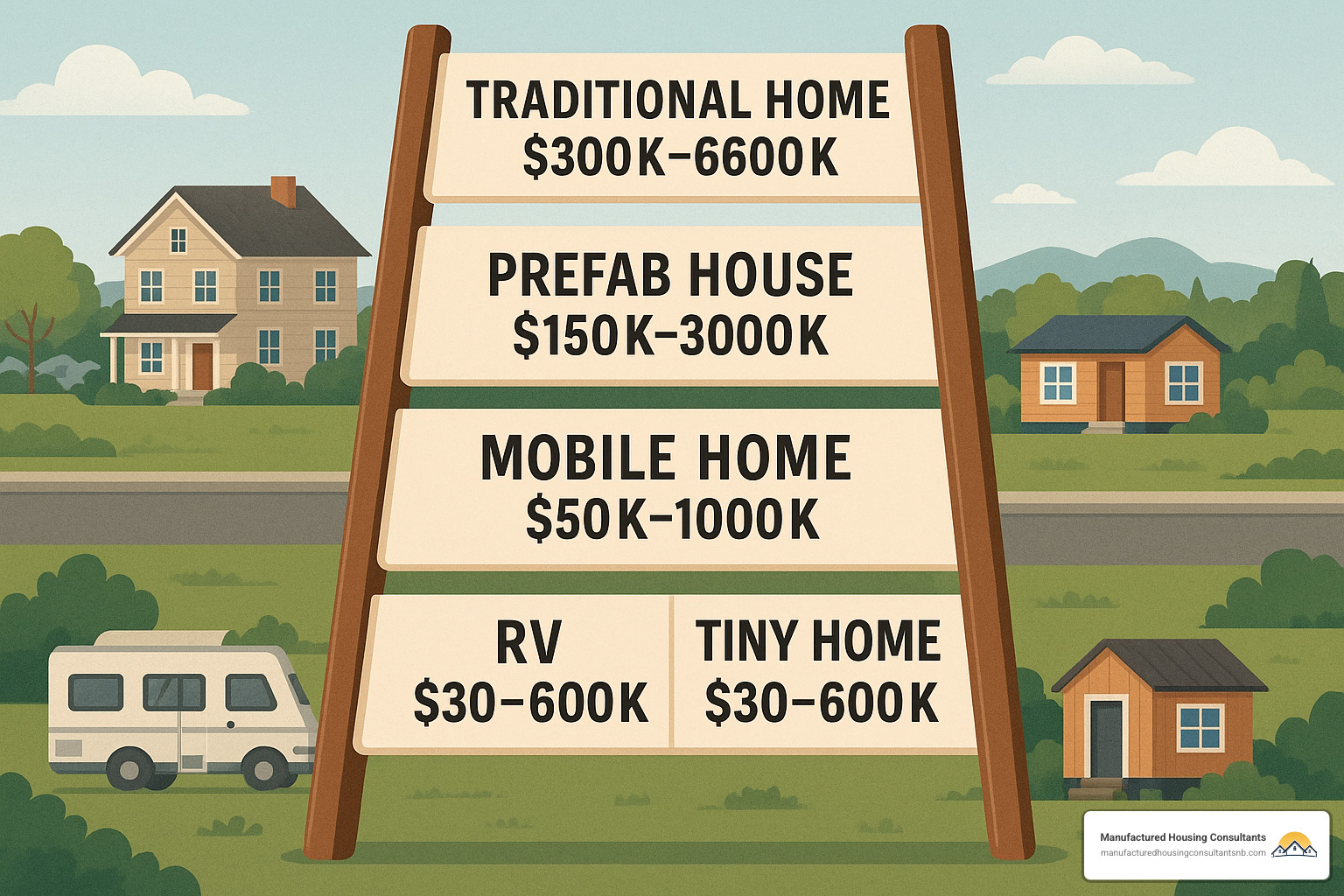

| Housing Option | Base Cost Range | Time to Move-In | DIY Potential | Financing Ease | Resale Value |

|---|---|---|---|---|---|

| Traditional Home | $250K-$500K+ | 6-12 months | Low | Excellent | Excellent |

| Prefab House | $50K-$200K | 3-6 months | Medium | Good | Good |

| Used Mobile Home | $5K-$50K | 1-4 weeks | High | Fair | Fair |

| Metal House Kit | $30K-$100K | 2-4 months | Very High | Fair | Good |

| Tiny Home Kit | $10K-$50K | 1-3 months | Very High | Limited | Fair |

| Panelized Cabin | $20K-$70K | 1-3 months | High | Limited | Good |

| Container Home | $15K-$50K | 2-4 months | High | Limited | Fair |

Let’s explore each option and find which might be your perfect budget-friendly match.

Refurbished Mobile Homes: Value Champion

If pure bang-for-your-buck is what you’re after, it’s tough to beat a quality refurbished mobile home. Here at Manufactured Housing Consultants in New Braunfels, we’ve helped countless Texas families find comfortable, surprisingly modern living spaces that cost a fraction of even the most inexpensive prefab houses on the market.

You can find used single-wides starting as low as $5,000-$10,000 (if you don’t mind some DIY TLC), while nicely renovated units typically range from $20,000-$40,000. Need more space? Double-wides offer generous square footage at $30,000-$60,000 for quality refurbished models.

What makes these homes such a smart buy? For starters, they’re ready when you are. Unlike prefabs that might keep you waiting months, a refurbished mobile home can often be yours within days. The permitting process is typically simpler too, especially if you’re placing it in an established mobile home park where utilities are already waiting.

Speaking of mobile home parks, many offer community amenities that would cost a fortune to build yourself—pools, playgrounds, even clubhouses. And if financing concerns you, we’ve got specialized programs designed specifically for mobile home purchases, including options for folks with less-than-perfect credit.

Just last month, we helped a young couple from San Antonio find a fully renovated 3-bedroom, 2-bath single-wide for $32,000. They were moving in their furniture just two weeks after first walking through our door—try matching that timeline with even the speediest prefab!

“We honestly expected to compromise on style,” they told us later. “But everything from the kitchen appliances to the bathroom fixtures was modern and fresh. And we paid less than half what our friends spent on their tiny prefab.”

More info about Cheap Prefab Houses

Metal House Kits & Barndominiums

There’s something undeniably cool about the industrial-chic aesthetic of metal homes and barndominiums—and they’ve absolutely exploded in popularity across Texas. These sturdy structures start with a durable steel frame that stands up beautifully to our Texas wind and weather.

Metal house kits typically range from $30,000 to $100,000 depending on size and features. One major advantage? Many companies offer free nationwide shipping—a significant saving compared to those hefty delivery charges for most inexpensive prefab houses.

These buildings are incredibly durable, often coming with 40+ year warranties on exterior materials. The open-span design means you won’t have load-bearing walls breaking up your floor plan, giving you complete freedom to design your interior. Your insurance company will likely reward you too, as metal structures often qualify for lower premiums due to their fire resistance.

Perhaps the biggest advantage is the DIY-friendly nature of these kits. Most come with pre-drilled components and clear instructions that make them accessible even to folks with modest construction skills. By tackling some or all of the assembly yourself, you could save $20,000-$40,000 in labor costs.

Many of our Texas customers are finding success with the “shell and finish” approach: they purchase a metal building kit, hire professionals to erect the basic structure, then finish the interior themselves over time as budget allows. This staged approach makes homeownership possible with a much lower initial investment than even the most inexpensive prefab house options.

At Manufactured Housing Consultants, while we don’t sell these kits directly, we’re happy to help coordinate your land preparation and foundation work to ensure your metal building has a proper start.

More info about Affordable Modular Homes

Tiny Home Kits Under $20K—A Smaller Take on an Inexpensive Prefab House

If you’re willing to accept the “less is more” philosophy, tiny home kits offer perhaps the most affordable path to brand-new home ownership. With prices starting around $8,000 for basic shells and $15,000-$20,000 for more complete packages, these compact dwellings deliver outsized savings.

The tiny house movement has matured beyond its minimalist beginnings. Today’s designs are surprisingly functional and comfortable, with clever storage solutions, multi-purpose furniture, and thoughtful layouts that make 200-400 square feet feel genuinely livable.

What makes tiny homes so appealing? For starters, that entry price—under $20,000 for many models—is less than a down payment on a conventional house. The ongoing savings are impressive too; with minimal space to heat, cool, and power, many tiny homeowners report utility bills 70-80% lower than in conventional housing.

Maintenance becomes refreshingly simple when you have less square footage to care for. Many tiny homes also offer mobility options, built on trailers that allow you to relocate as needed—perfect for those whose lives might take them in unexpected directions.

For the environmentally conscious, tiny homes shine bright. Many kits come designed with solar power capabilities, rainwater collection systems, and composting toilets either standard or as easy add-ons.

One standout option we’ve seen customers love is the “Incredibox” tiny house, starting at just $19,900 for a fully finished 8×16 model. Thanks to innovative factory assembly, these homes can be built in just 10 hours, allowing for quick delivery and setup.

While traditional mortgage lenders might raise an eyebrow at tiny homes, several financing paths have emerged, including personal loans, RV loans for certified tiny homes on wheels, manufacturer financing programs, and specialized lenders like LightStream and SoFi who understand the tiny home market.

If you’re considering placing a tiny home in the New Braunfels area, drop by our office—we’re happy to help steer local zoning requirements and connect you with services to prepare your site properly.

Panelized DIY Cabin Packages

Think of panelized cabin kits as the perfect middle ground between complete inexpensive prefab houses and traditional stick-built construction. These clever kits include pre-cut, pre-framed wall sections, roof trusses, and floor systems that arrive ready for assembly—dramatically cutting construction time while giving you plenty of design flexibility.

Starting around $20,000 for basic models and ranging up to $70,000 for larger designs with premium features, panelized cabins offer meaningful savings over both traditional construction and most factory-built prefabs.

The beauty of the panelized approach is how quickly you can get your structure weather-tight. Most designs can be assembled to a protected condition in just 1-3 days, shielding your investment from rain, snow, and other elements that can damage exposed materials. Since everything’s precisely cut at the factory, you’ll also generate minimal waste on site.

Unlike complete prefabs, panelized kits give you the freedom to finish interiors at your own pace and budget. Maybe you complete the kitchen and bathroom first, then tackle bedrooms as funds allow. The flat-packed panels are also easier and less expensive to transport than complete modules.

The key to maximizing savings is taking on some assembly and finishing work yourself. While raising the structural shell requires basic carpentry skills and usually 3-4 people for safety, interior finishing can be completed gradually by homeowners with average DIY abilities. You’ll need basic tools like a hammer or nail gun, circular saw, drill, level, and ladders or scaffolding.

For Texas builders, it’s worth noting that most quality panelized kits are engineered to meet or exceed local building codes, including our wind and energy requirements. At Manufactured Housing Consultants, we can help ensure your foundation is properly designed to support your chosen panelized system.

Shipping Container Conversions: Industrial Chic on a Budget

For the truly adventurous homebuilder, shipping container conversions offer perhaps the most unconventional alternative to an inexpensive prefab house. Starting with industrial steel containers (typically 20′ or 40′ long), these projects transform utilitarian boxes into surprisingly comfortable living spaces with undeniable character.

Basic single-container homes can cost as little as $15,000-$30,000 when substantially DIY, while more elaborate multi-container designs range from $50,000-$150,000—still competitive with many prefab options.

The structural strength of shipping containers is impressive—they’re designed to withstand ocean transport and stacking, providing exceptional durability against the elements. This modular nature also means you can start with one container and add more over time as your needs and budget grow.

One of the biggest advantages is that your basic waterproof, secure shell exists from day one. You’re immediately protected from the elements, allowing you to work on the interior at your own pace. There’s also something satisfying about the sustainability angle—repurposing these containers keeps them out of the waste stream.

The conversion process typically involves cutting openings for doors and windows, adding insulation (spray foam works best for maximizing space), installing utilities, finishing interior walls, and optionally adding exterior cladding. While container homes offer substantial savings, they do present unique challenges—you’ll need to address insulation carefully due to steel’s high thermal conductivity, and you’ll need specialized cutting tools for creating openings.

Some jurisdictions are still catching up to this building style, so permits can be challenging. And yes, standard containers are just 8′ wide, which does create some design constraints.

For those interested in container homes around New Braunfels, we’re happy to provide guidance on local regulations and connect you with contractors who understand this specialized construction method.

Scientific research on construction waste

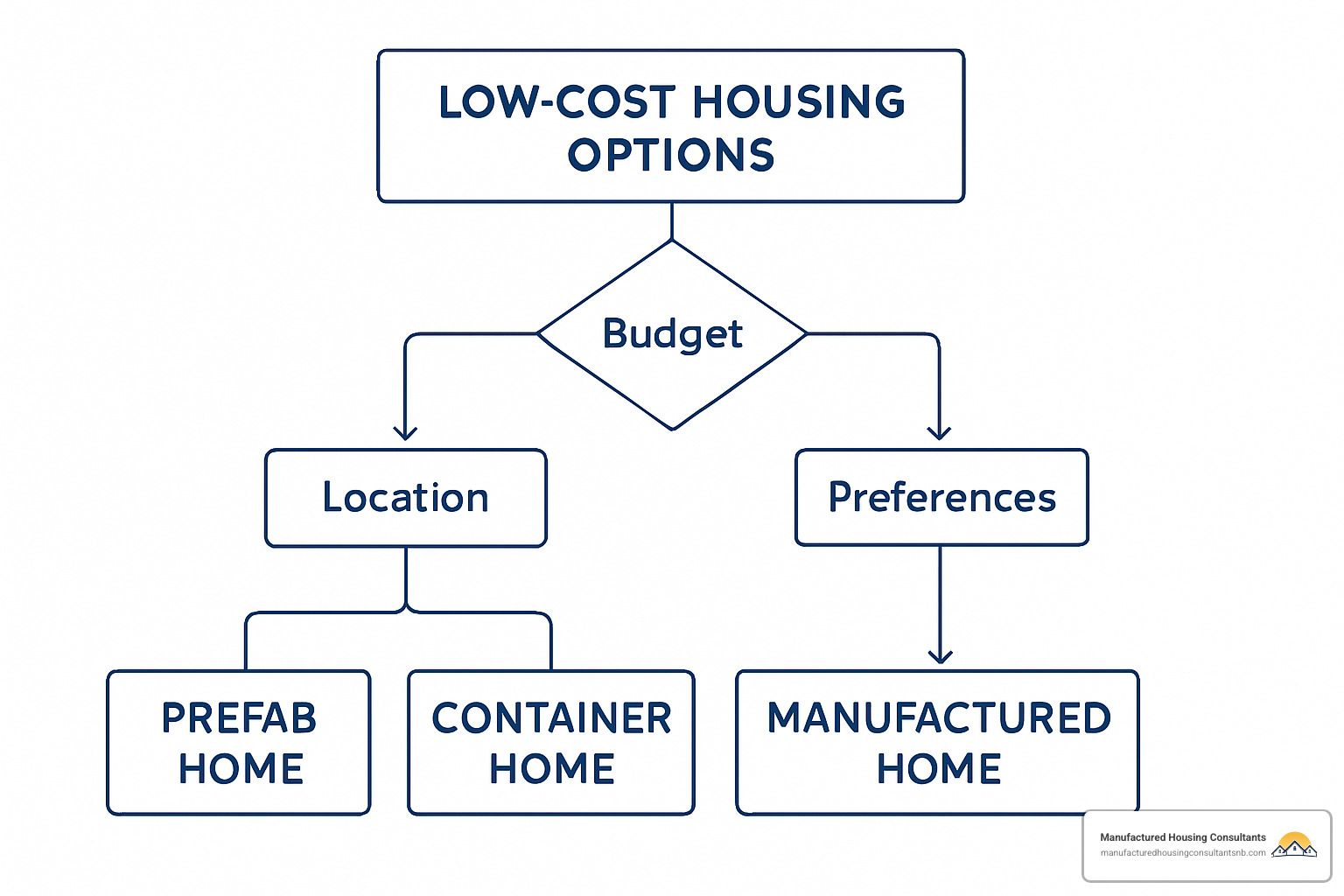

How to Pick the Best Low-Cost Path & Next Steps

Finding your ideal path to affordable homeownership is like putting together a puzzle where your budget, timeline, and skills all need to fit perfectly. At Manufactured Housing Consultants, we’ve guided hundreds of Texas families through this decision process, and we’ve learned that the right choice often comes down to a few key factors.

When comparing an inexpensive prefab house with the alternatives we’ve discussed, start by taking a hard look at your total budget. Not just the sticker price, but everything that goes with it. Land preparation alone can surprise many first-time buyers—clearing, grading, and foundation work often adds $5,000-$15,000 before you even start building. Utility connections might tack on another $3,000-$10,000 depending on your property’s distance from existing services.

“I thought I’d found the perfect tiny home kit for $18,000,” shared Maria, one of our recent customers. “Then I realized I needed another $12,000 for site work and permits. Having Manufactured Housing Consultants walk me through these hidden costs saved me from a budget disaster.”

Your timeline matters just as much as your budget. If you’re needing a place to live quickly, a refurbished mobile home might be your best bet—many of our customers move in within 1-4 weeks of purchase. Container homes and panelized cabins typically take 2-3 months from purchase to move-in, while metal building kits usually require 2-4 months to complete.

Be honest with yourself about your DIY skills too. We’ve seen too many unfinished projects where enthusiasm outpaced ability. If you’ve never held a hammer, a fully-finished mobile home might make more sense than a container conversion project. For those with solid carpentry skills, the sweat equity you put into a panelized cabin could save you $20,000 or more in labor costs.

Your land situation creates its own set of requirements. That sloped lot with beautiful views might be perfect for a pier-foundation tiny home but problematic for a mobile home placement. Local zoning also varies dramatically—some Texas counties have minimal restrictions, while others have specific requirements about foundation types, minimum square footage, and exterior finishes.

“We found the perfect five acres outside New Braunfels,” James told us after purchasing one of our double-wide homes. “But we had no idea how to get water and electricity to the back of the property. The land improvement team at Manufactured Housing Consultants handled everything, from clearing the pad site to running utilities.”

Financing realities will often narrow your options considerably. Traditional mortgage lenders typically won’t touch tiny homes or container projects, pushing you toward higher-interest personal loans instead. Mobile and manufactured homes can access specialized chattel loans, though rates are typically 2-4% higher than conventional mortgages. For DIY builds, many buyers find themselves cobbling together funding from savings, credit cards, and personal loans—a strategy that works but requires careful planning.

Think about your long-term plans too. A refurbished mobile home might be perfect for your five-year plan but could depreciate over time. Metal buildings and panelized cabins typically maintain their value better, especially with quality finishes and good maintenance. Insurance costs also vary dramatically—some insurers charge premium rates for unconventional construction methods.

Warranty protection differs significantly between options as well. When you purchase a refurbished mobile home from us, it typically comes with a 30-90 day limited warranty. New manufactured homes usually include a one-year comprehensive warranty plus 5-10 years of structural coverage. Kit homes and DIY builds often limit warranty coverage to individual components, leaving the overall structure unprotected.

Ready to move forward? If you’re in the New Braunfels or greater Texas area, we’d love to help. Stop by our dealership to tour available homes, or schedule a consultation with one of our housing specialists who can walk you through all your options. We can help with financing pre-approval through our network of specialized lenders, discuss land improvement services if your property needs preparation, and steer the sometimes confusing world of local building regulations.

With over a decade of experience helping Texans find affordable housing solutions, we understand that the path to homeownership isn’t one-size-fits-all. Whether you choose an inexpensive prefab house or one of the alternatives we’ve discussed, our team is committed to helping you find the perfect balance of affordability, quality, and convenience.

The best home isn’t the one with the fanciest features or the biggest price tag—it’s the one that gives you peace of mind and fits your life. We look forward to helping you find yours.