Pouring the Perfect Base: Slab Foundations for Your Mobile Home

Get the best stability & value! Explore pros, cons, and costs of a slab foundation for mobile home, ideal for Texas land & FHA/VA loans.

Why a Solid Foundation Matters for Your Texas Mobile Home

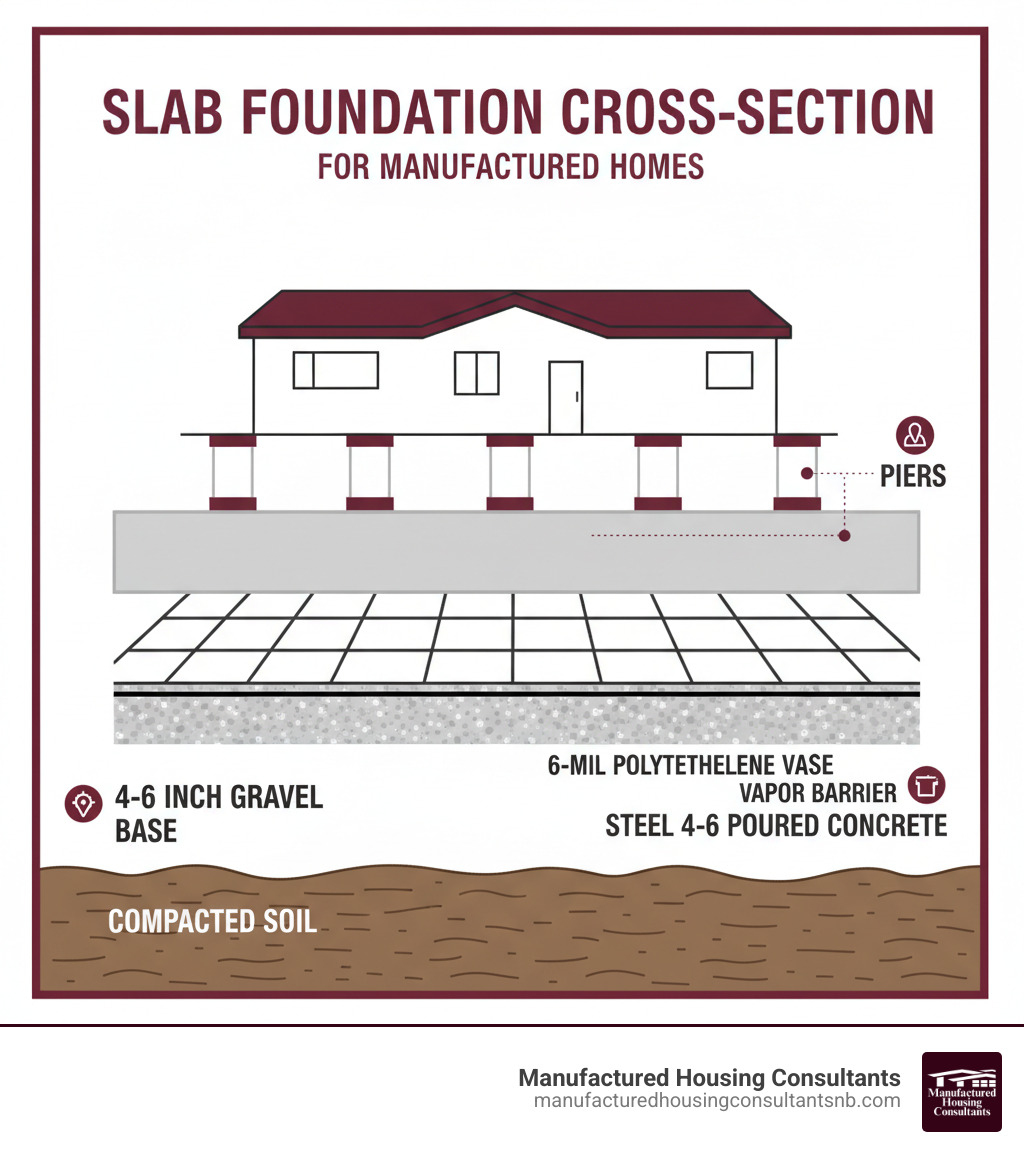

A slab foundation for mobile home installation is a poured concrete platform, typically 4-6 inches thick, that transforms your manufactured home from a temporary structure into a permanent, valuable asset. Here’s what you need to know:

What Is a Slab Foundation?

- A monolithic concrete pad poured directly on prepared ground

- Creates a stable, level platform for your manufactured home

- Includes gravel base, vapor barrier, and steel reinforcement

- Lifts your home slightly to create a small crawl space

- Qualifies as a permanent foundation for financing purposes

Key Benefits:

- Permanent Status – Opens doors to FHA and VA loans

- Increased Value – Homes on slabs appreciate like traditional houses

- Texas-Tough – Resists Gulf Coast flooding, high winds, and expansive clay soils

- Low Maintenance – Lasts 50+ years with minimal upkeep

- Pest Barrier – No crawl space means fewer termites and rodents

The Trade-offs:

- Higher upfront cost ($4,000-$12,000 vs. $3,000-$8,000 for piers)

- Requires a level lot

- Limited utility access after installation

- 5-7 day installation timeline

If you’re buying a manufactured home in Texas, especially in areas like New Braunfels with challenging soil conditions, a slab foundation offers best stability and long-term value. It’s not the cheapest option upfront, but it’s often the smartest investment for permanent homeownership.

At Manufactured Housing Consultants, we’ve helped countless Texas families steer foundation choices based on their specific land, budget, and financing needs. Our local expertise means we understand how New Braunfels’ clay soil, occasional flooding, and building codes affect your foundation decision.

Terms related to slab foundation for mobile home:

The Core Details of a Slab Foundation for Mobile Home

When you’re considering a slab foundation for mobile home installation, it’s helpful to understand what makes it different from other options. Unlike traditional site-built homes where the slab often becomes the finished floor, your manufactured home arrives with its own complete floor system—insulation, finished surfaces, utilities and all. The concrete slab we pour becomes the rock-solid platform underneath, providing structural support and environmental protection that lasts for decades.

Think of it as building the perfect stage for your home to perform on for the next 50+ years.

Pros and Cons of a Slab Foundation for a Mobile Home

Choosing the right foundation affects everything from your home’s stability to your ability to get financing. A slab foundation for mobile home installation offers some compelling advantages, especially here in Texas. But let’s be honest—it’s not the right choice for every situation or every budget.

Here’s what you need to know about both sides of the equation:

The Advantages That Make Slabs Stand Out

The biggest win with a slab foundation is permanent foundation status. This isn’t just a technical detail—it’s the key that open ups better financing options. When your manufactured home sits on a properly constructed slab, lenders and local authorities classify it as “real property” instead of personal property. That means you can qualify for conventional mortgages, FHA loans, and VA loans with their typically lower interest rates and better terms.

This classification is crucial for securing these types of loans. The U.S. Department of Housing and Urban Development (HUD) outlines the specific criteria for what constitutes a permanent foundation. For homeowners and builders, The Permanent Foundations Guide for Manufactured Housing is the definitive resource for ensuring your foundation meets all federal financing requirements.

Your resale value gets a serious boost too. Homes on permanent foundations appreciate at nearly the same rate as traditional site-built homes. We’re talking about a potential 10-30% increase in value compared to homes on non-permanent foundations. Your manufactured home stops being a depreciating asset and becomes a real investment in your future.

If you’ve spent any time in Texas, you know our soil can be challenging. Those expansive clay soils are famous for swelling when wet and shrinking when dry. A monolithic slab foundation distributes your home’s weight evenly across the entire surface, making it incredibly resistant to the shifting and settling that can cause problems with other foundation types. Engineers sometimes describe it as a ship that sails on top of heaving soil conditions—and that’s exactly what you want in places like New Braunfels.

For folks near the Gulf Coast or in high-wind areas, wind and flood resistance becomes critical. Ground anchors embedded directly in the concrete, combined with steel straps, create an incredibly secure connection between your home and the ground. In flood-prone areas, we can lift the slab to raise your home’s floor above the 100-year base flood elevation that FEMA requires. The slab itself becomes part of your flood protection strategy.

There’s also the pest and moisture barrier benefit that homeowners really appreciate. With no open crawl space, termites, rodents, and other unwanted visitors have a much harder time getting under your home. The concrete itself, especially when paired with a 6-mil vapor barrier, blocks moisture from rising up from the ground. This keeps the space under your home healthier and drier year-round.

From a maintenance perspective, slabs are wonderfully low-key. Once that concrete cures, you’re looking at 50+ years of service with minimal upkeep required. No rotting wood piers to replace, no settling issues to address every few years. It’s a set-it-and-forget-it solution that gives you peace of mind.

The Drawbacks Worth Considering

Let’s talk money first. The higher upfront cost is usually the biggest hurdle for folks considering a slab. You’re typically looking at $4,000 to $12,000 depending on your home’s size and site conditions, compared to $3,000 to $8,000 for pier-and-beam foundations. That’s a real difference when you’re working within a budget, even though the long-term value often justifies the investment.

Utility access becomes tricky with a slab. Your plumbing and electrical lines get embedded in or run beneath the concrete. If you ever need to repair a water line or replace electrical conduit, you’re potentially looking at breaking through concrete to get to it. With a pier foundation, you can usually just crawl underneath. This doesn’t mean repairs are impossible—just more complicated and potentially more expensive.

You’ll also need a relatively level lot to make a slab work economically. If your land has significant slope, the excavation and grading work required to create a level pad can get expensive quickly. Slabs work beautifully on flat terrain, but they’re not usually the best choice for hillside properties.

Finally, there’s the potential for cracking if the installation isn’t done right. Inadequate ground preparation, poor concrete mix, or missing reinforcement can lead to problems down the road. This is especially true in our Texas clay soils, where proper engineering and installation technique really matter. That’s why working with experienced professionals who understand local soil conditions makes such a difference.

At Manufactured Housing Consultants, we’ve helped countless New Braunfels families weigh these pros and cons based on their specific situation—their land, their budget, and their long-term plans for their home.

The Installation Process: From Dirt to Done

Installing a slab foundation for mobile home is a carefully choreographed process that typically takes 5-7 days from start to finish, weather permitting. Each step builds on the previous one to create a foundation that will support your home for decades.

Getting the Engineering Right

Everything starts with a professional engineer creating a customized plan for your specific home and site. This isn’t optional—it’s required for FHA and VA financing, and it’s just good practice. The engineer considers your home’s size and weight, analyzes your soil conditions, and checks local building codes. Their plan specifies exactly how thick the slab needs to be, where the rebar goes, whether post-tensioning cables are needed, and how the home will be anchored. This blueprint guides every step that follows.

Preparing the Ground

The crew begins by clearing away debris, vegetation, and any topsoil that won’t provide adequate support. Proper grading is crucial here—we need water to drain away from your foundation, not toward it. If your lot has any slope, this is where we do the excavation to create a perfectly level pad. The pad should extend about one foot beyond your home’s dimensions on all sides, giving you room for proper drainage and skirting later. Once the pad is level, we thoroughly compact the soil to create a stable base that won’t settle over time.

Building the Forms and Base Layers

Wooden or metal forms go up around the perimeter, defining the exact shape and size of your slab. Inside these forms, we spread a 4-6 inch layer of gravel or sand and compact it thoroughly. This granular base layer helps with drainage and prevents moisture from wicking up through the concrete. On top of the gravel goes a 6-mil polyethylene vapor barrier—essentially a thick plastic sheet that blocks ground moisture from ever reaching your home. This simple layer makes a huge difference in preventing moisture problems down the road.

Adding Strength with Steel

Steel reinforcement goes in next, following the engineer’s specifications exactly. Rebar or steel mesh provides tensile strength that plain concrete lacks, helping the slab resist cracking from soil movement or your home’s weight. In areas with particularly challenging soil conditions, we might also install post-tensioning cables. These cables get tightened after the concrete cures, dramatically increasing the slab’s strength and load-carrying capacity. It’s like giving your foundation superpowers.

Roughing in Utilities

Before we pour concrete, any plumbing lines, electrical conduits, or other utilities that need to run through the slab get installed. This step requires careful planning because once that concrete hardens, these lines are locked in place. This is why the earlier engineering phase is so important—we need to get it right the first time.

The Pour and Finish

Pour day is when everything comes together. High-quality concrete, typically 4-6 inches thick, fills the forms. The crew works quickly to spread and level the concrete while it’s still workable, using screeds and floats to achieve a smooth, uniform surface. The goal is a monolithic pour—one continuous piece of concrete without weak joints or seams.

Curing Time

Once the concrete is poured, patience becomes essential. The slab needs several days to cure properly—this is a chemical process where the concrete gains its full strength. We protect the slab during this time, often covering it or keeping it moist to prevent rapid drying that could cause cracks. Rushing this step compromises everything that came before it, so we make sure the slab gets the time it needs.

Setting Your Home

After the concrete has fully cured, your manufactured home arrives and gets carefully positioned on the slab. Steel straps and ground anchors embedded in the concrete permanently secure the home, providing resistance against wind uplift and lateral forces. This final connection between home and foundation is what makes the whole system work.

Understanding Ventilation and Access

Even with a slab, there’s still a small space between the concrete and your home’s floor system. This area needs adequate cross-ventilation to prevent moisture buildup—similar to other foundation types. If we’re using an insulated slab design (sometimes called a frost-protected shallow foundation), we might close off perimeter vents during cold months to trap heat in the soil and prevent frost issues in North Texas.

The utility access question is worth understanding upfront. With everything embedded in or running beneath the slab, future repairs require more planning than with a crawl-space foundation. This is why that initial utility rough-in phase is so critical—quality installation from the start prevents most problems later. When repairs are needed, they’re definitely possible, just more involved.

Cost and Comparison to Other Foundation Types

Let’s talk numbers, because understanding the investment helps you make the right decision for your situation. A slab foundation for mobile home installation typically runs between $4,000 and $10,000, with some larger or more complex installations reaching $12,000. The 5-7 day installation timeline means you’re not waiting weeks to get your home set up.

Here’s how slabs compare to the other common option—pier and beam foundations:

| Feature | Slab Foundation | Pier & Beam Foundation |

|---|---|---|

| Cost | $4,000-$12,000 | $3,000-$8,000 |

| Installation Time | 5-7 days | 2-4 days |

| Durability | 50+ years | 20-30 years |

| Best Use in Texas | Level lots, high-wind zones, areas with expansive clay soil | Sloped lots, areas needing easy utility access |

Several factors affect where your project falls in that cost range. Your home’s size obviously matters—a larger home needs a larger slab. Soil conditions play a big role too. If your soil requires special preparation or additional reinforcement, costs go up. Site accessibility affects the price, as does current concrete and rebar pricing. In the New Braunfels area, we’ve seen costs vary based on these factors, which is why we always provide customized quotes based on your specific situation.

The higher upfront cost compared to pier foundations often surprises people, but consider the full picture. That extra $1,000-$4,000 buys you decades of additional lifespan, access to better financing options, increased resale value, and minimal maintenance needs. It’s an investment that typically pays for itself over the years you’ll own the home.

If you’re curious about other foundation options and how they might work for your specific land and needs, check out our guide to Mobile Home Foundation Types. Every property is different, and at Manufactured Housing Consultants, we help folks in New Braunfels and the surrounding area figure out which foundation type makes the most sense for their unique situation.